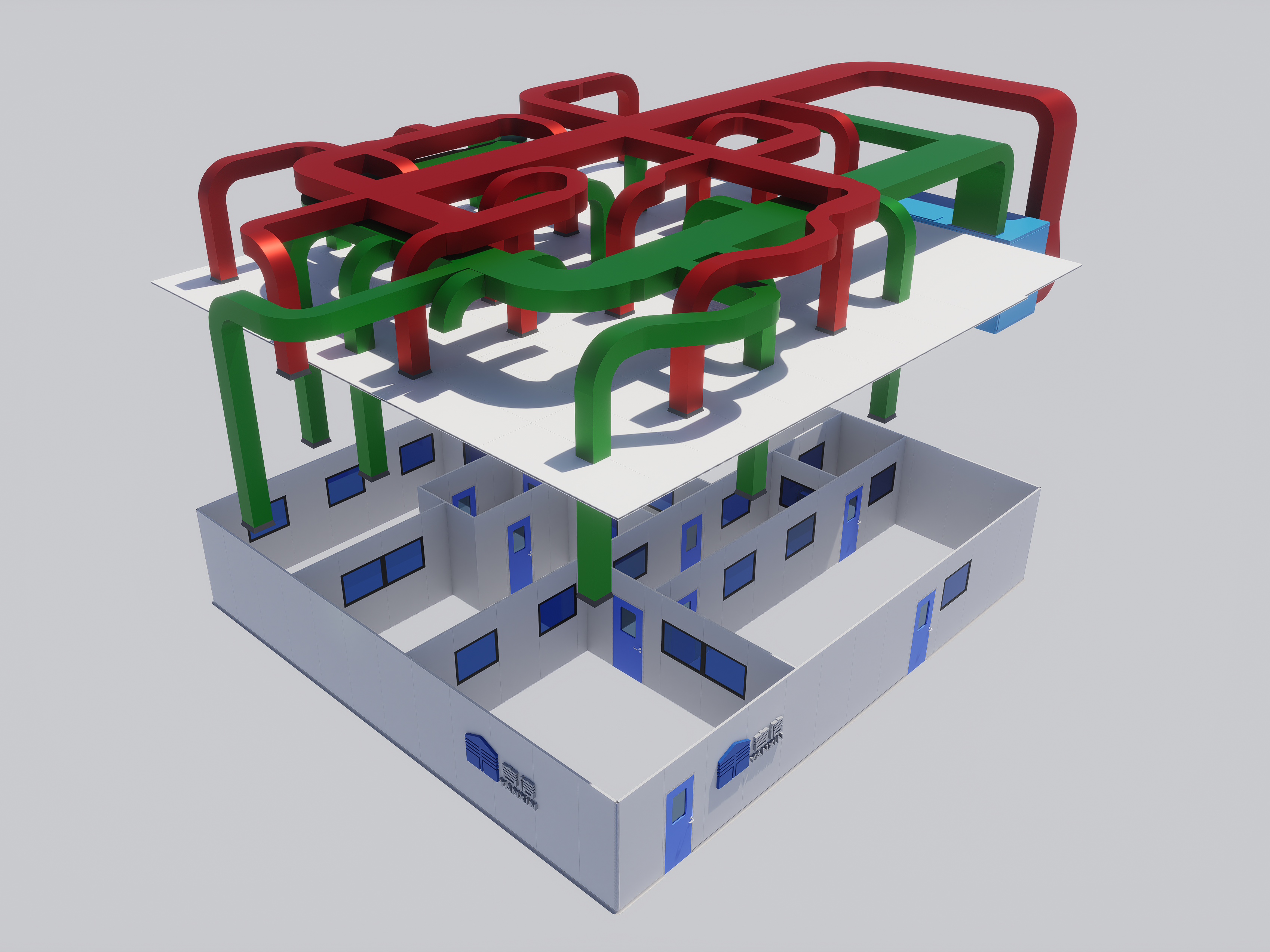

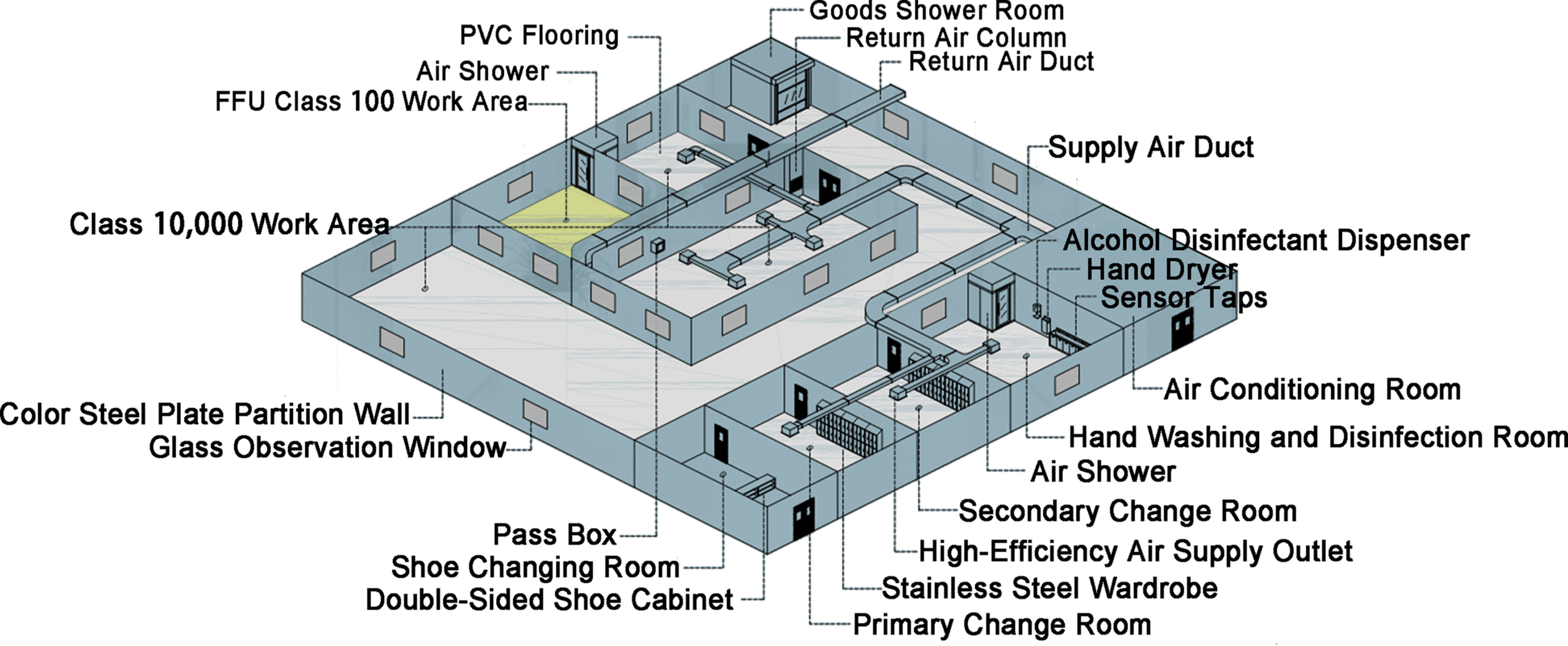

This 3D rendering shows a complete cleanroom system that combines modular wall panels with a precision-engineered HVAC network. Red ducts represent the supply system and green ducts the return/exhaust, ensuring controlled airflow, stable pressure differentials, and ISO-class particulate control.

As a trusted partner, we provide a full turnkey service:

Integrated Cleanroom & HVAC Solution

- Design & Engineering – Detailed airflow modeling and layout planning to meet international cleanroom standards.

- Material Supply – Certified cleanroom panels, doors, windows, and walkable ceiling systems.

- Fabrication & Installation – Professional assembly of ducts, modular walls, and ceilings for efficient, dust-free construction.

- Testing & Validation – Comprehensive performance verification for temperature, humidity, and contamination control.

This integrated approach ensures regulatory compliance, scalability, and long-term reliability for pharmaceutical, semiconductor, and other high-tech applications.

As Your One-Stop Cleanroom material manufacture Partners.

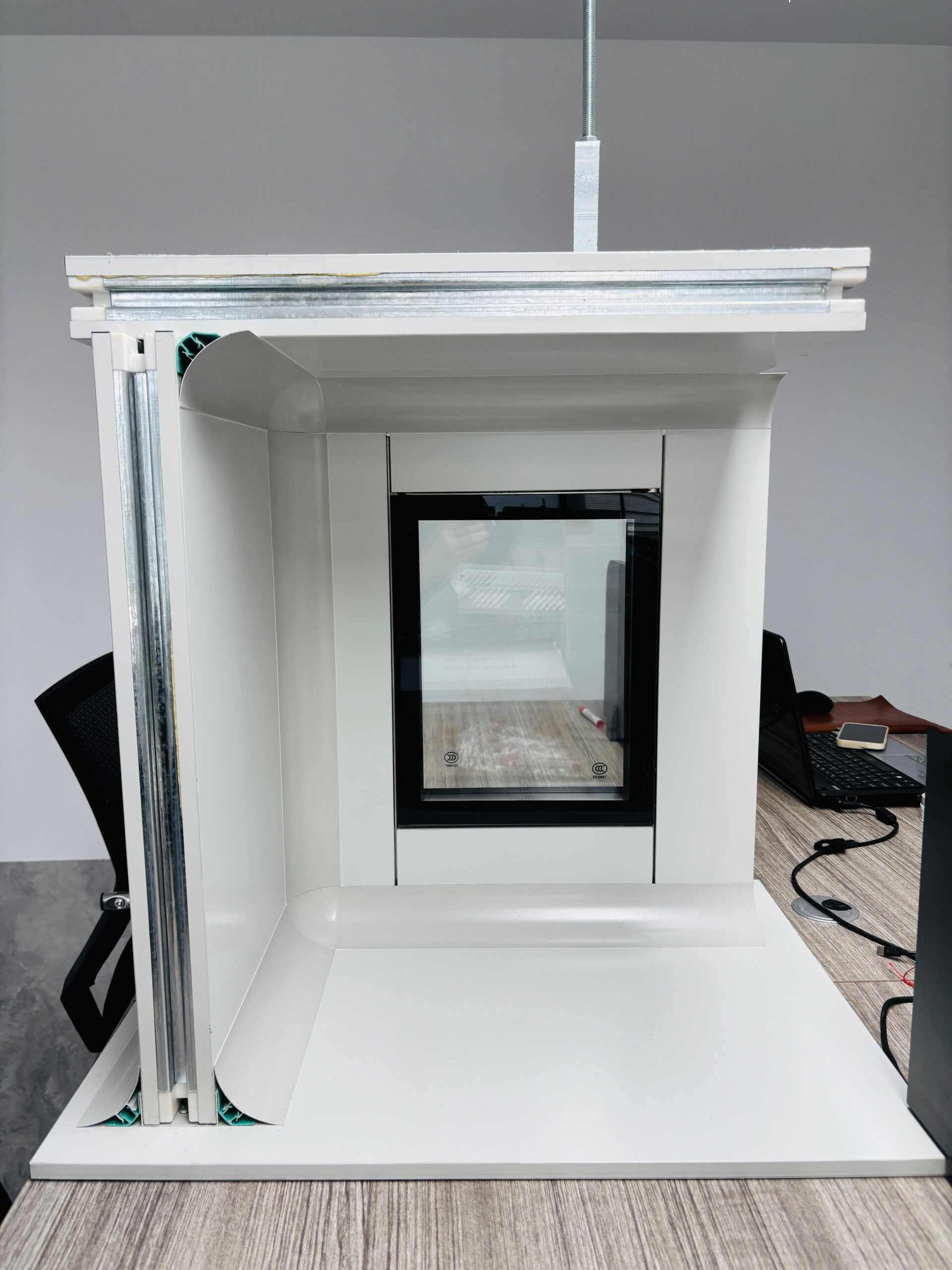

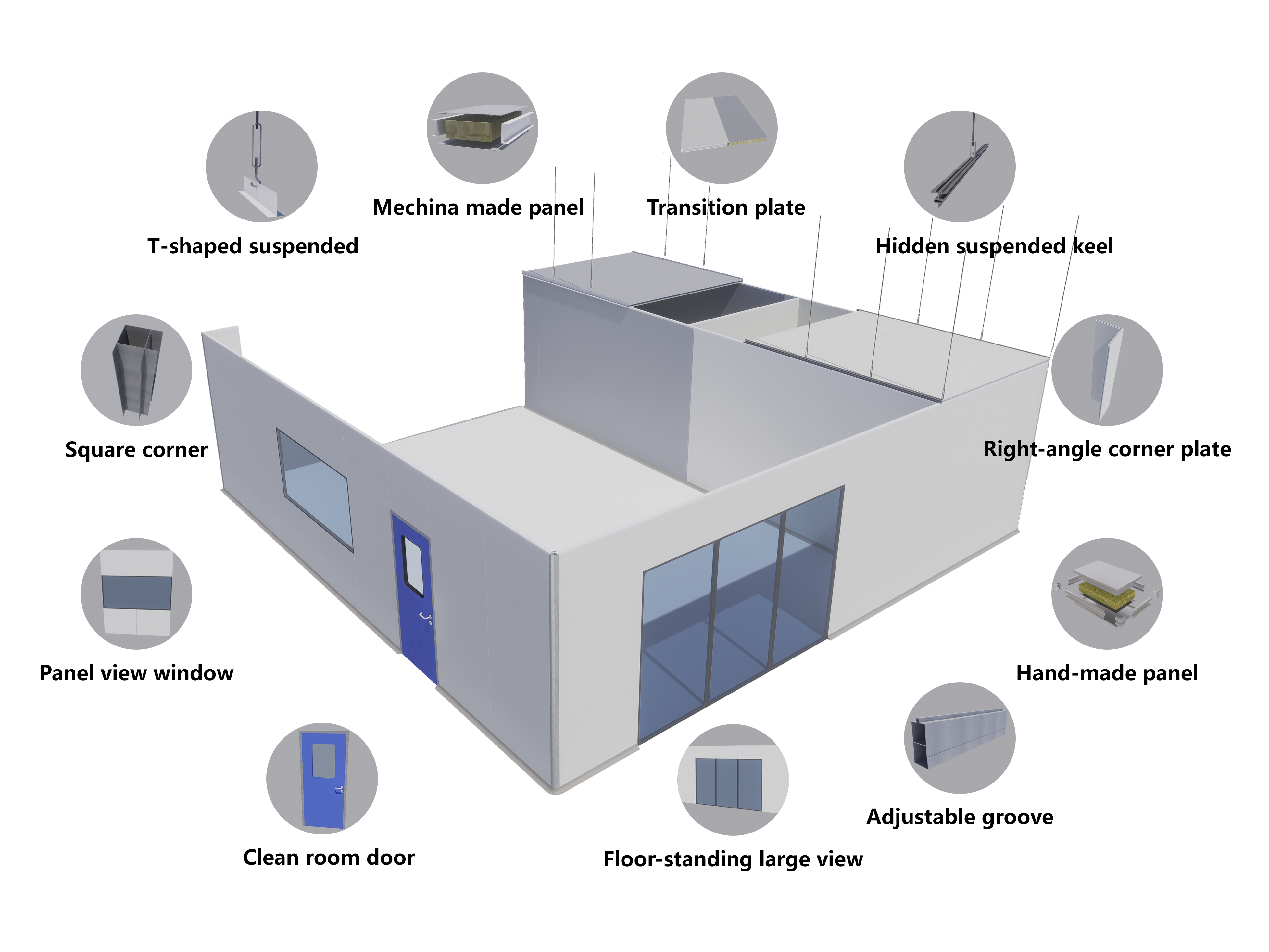

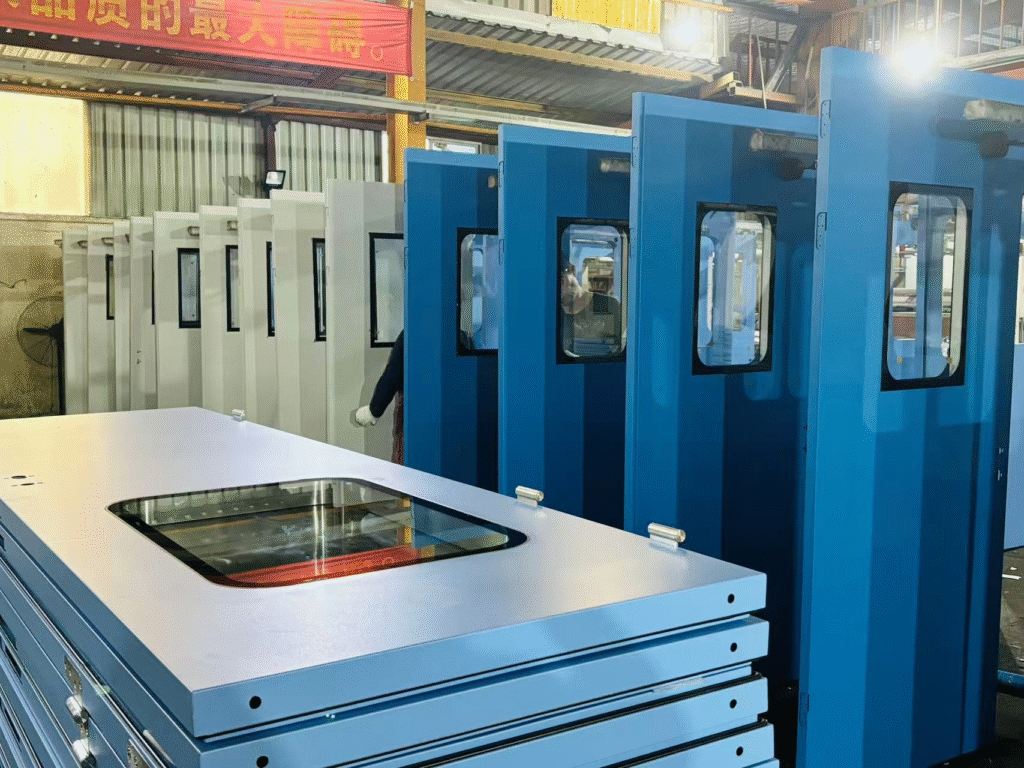

This illustration showcases our integrated cleanroom construction components, designed for high-performance environments such as pharmaceuticals, electronics, and biotechnology.

As a specialized material manufacturer, we produce and supply every key element required for a modular cleanroom:

Complete Cleanroom Panel & Accessories System

Panels: Precision-engineered hand-made and machine-made wall panels for airtight, smooth surfaces.

Doors & Windows: Custom cleanroom doors, panel-view windows, and floor-standing large view windows for visibility and easy access.

Structural Accessories: T-shaped suspended supports, hidden suspended keels, transition plates, square corners, and right-angle corner plates ensure seamless installation and a clean finish.

Detail Components: Adjustable grooves and other trim pieces for tight, contamination-free joints.

At Jiangsu Yanxin, our products are manufactured to strict quality standards, ensuring excellent durability, chemical resistance, and compliance with ISO and GMP cleanroom requirements.

By choosing our materials, you gain a single-source solution for walls, ceilings, doors, and accessories—streamlining your cleanroom project with reliable, precision-built components.

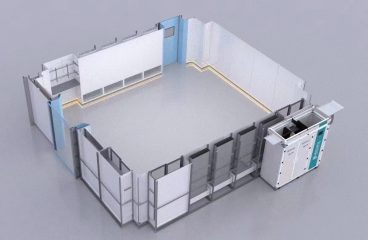

SOLUTIONS FOR DIFFERENT INDUSTRY

Hospital operating room structure

We work with multiple industries overseas, focusing on quality and cleanliness requirements to convey a professional and safe image to patients, operators and doctors.

An operating room construction project is more than material supply: it also means basic and detailed design, site management, professional installation, validation and certification.

Electrical, wall and ceiling materials certified to international standards (CE, ISO900).

Phramaceutical factory structure

MORE ON OUR CLEANROOM PRODUCTS

CLEANROOM PANEL SELECTION(MATERIAL)

Cleanroom panels are the backbone of modular cleanrooms. The choice of rockwool, honeycomb, PU/PIR, or HPL/stainless-steel panels depends on project requirements such as fire resistance, cost, chemical exposure, and cleanliness class. Proper selection and installation guarantee both performance and long-term cost efficiency. We ensure you will find the ideal solution for your needs, Contact us and find the best match of your program.

CLEANROOM DOOR SELECTION

Cleanroom doors in modular cleanrooms are not just entry points but critical barriers that ensure airtightness, contamination control, and compliance with ISO/GMP standards. The choice of swing, sliding, or hermetic doors — combined with suitable materials like stainless steel, HPL, or coated steel — depends on application-specific needs such as hygiene, fire safety, and pressure control. JIANGSU YANXIN offers you various kind of cleanroom door, you can find the ideal choice for the best match of your project.

CLEANROOM ACCESSORIES

Cleanroom accessories in modular cleanrooms are not just add-ons; they are essential functional elements that guarantee compliance, improve operational efficiency, and enhance user safety. The careful selection of windows, pass boxes, air showers, covings, lighting, and furniture ensures that modular cleanrooms remain flexible, compliant, and cost-effective throughout their lifecycle.