A Modular Cleanroom is a prefabricated, highly controlled environment designed to maintain specific cleanliness levels by controlling airborne particles, temperature, humidity, and pressure.

Unlike traditional cleanrooms built on-site with permanent construction methods, modular cleanrooms are pre-engineered, factory-fabricated, and assembled on-site for rapid deployment and flexible configuration.

JIANGSU YANXIN provides various CLASSIFIED MODULAR CLEANROOM to meet your specific requirements.

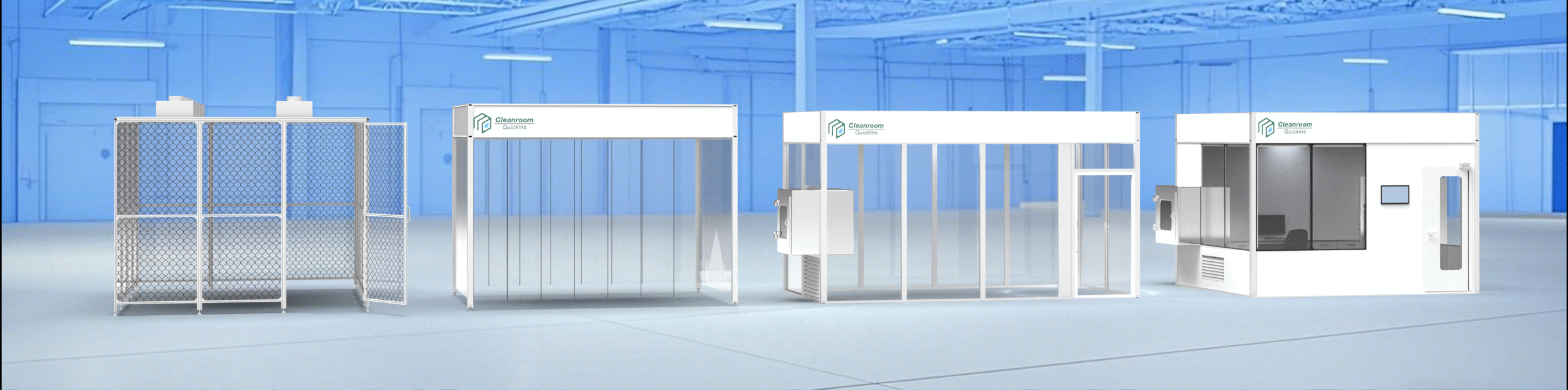

PRODUCTS:

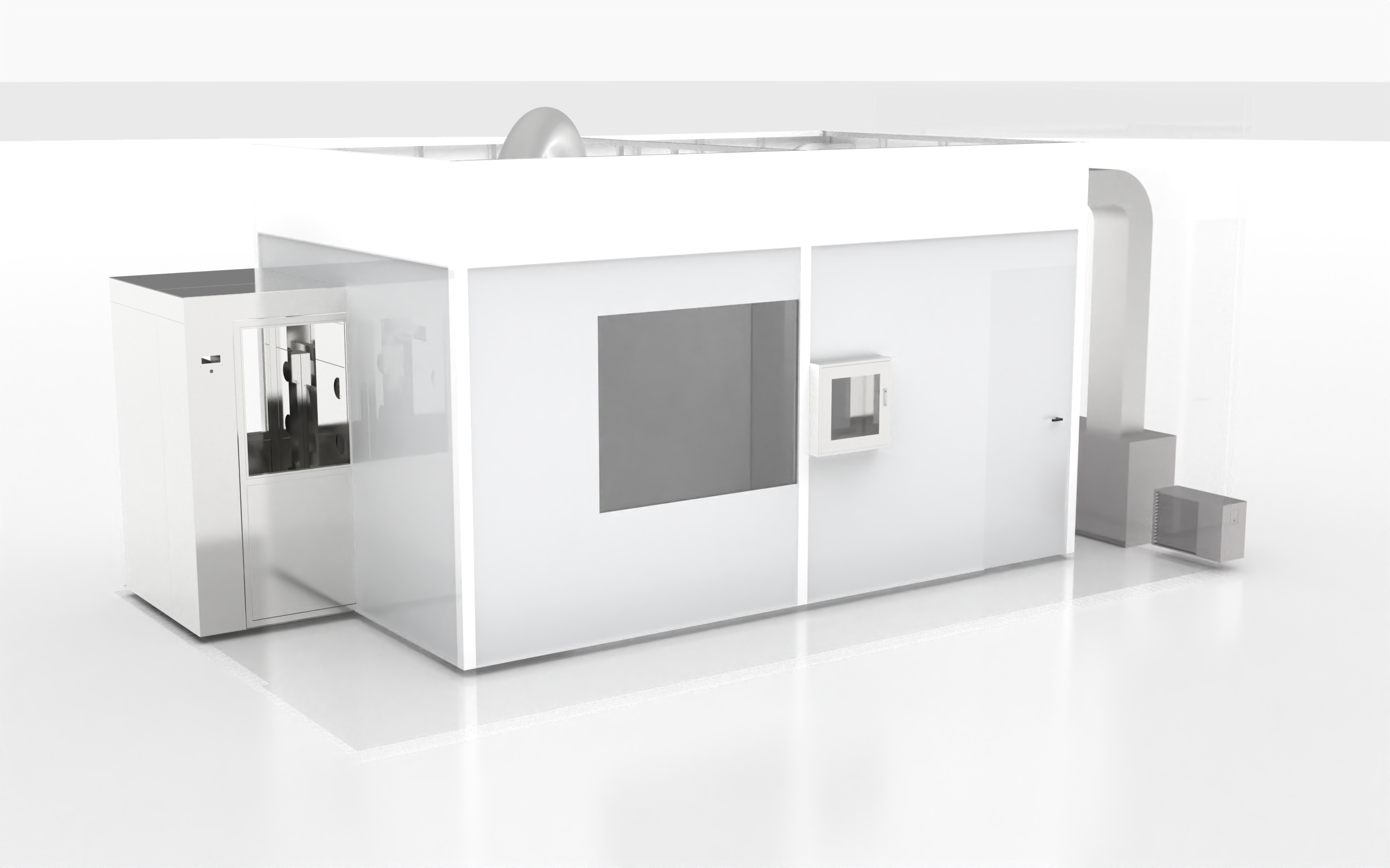

CLEAN BOOTH 1

CLEAN BOOTH 2

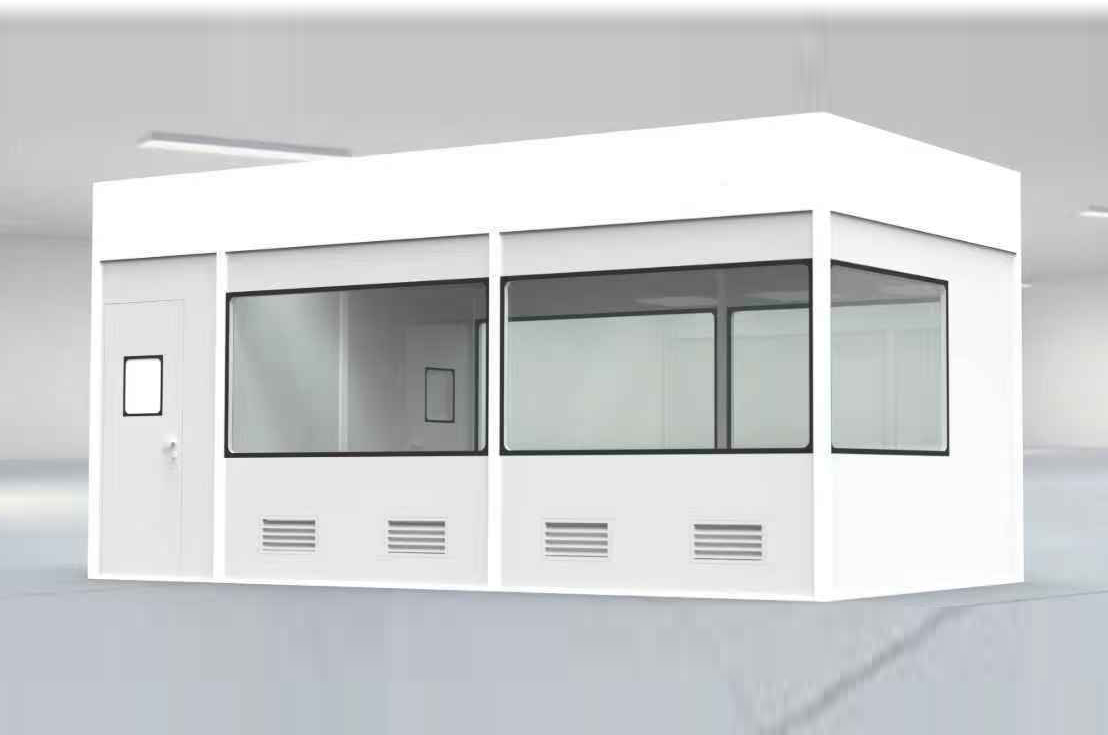

CLEAN ROOM 1

CLEAN ROOM 2

Modular Clean Booth | Modular Clean Room | |

Structural Frame | Custom aluminum profiles, 80×80×2.0 mm aluminum profiles, | |

Enclosure Material | PVC curtain, 1–3 mm thick | 50mm handmade cleanroom panel |

Air Return Type | Only Internal circulation | Optional external circulation / internal circulation |

Cleanroom Class | Iso 5-9 | Iso 3-9 |

Support Type | Self-supporting | |

Max Door Width | 6m, depth can be extended | |

Our Modular Cleanroom:

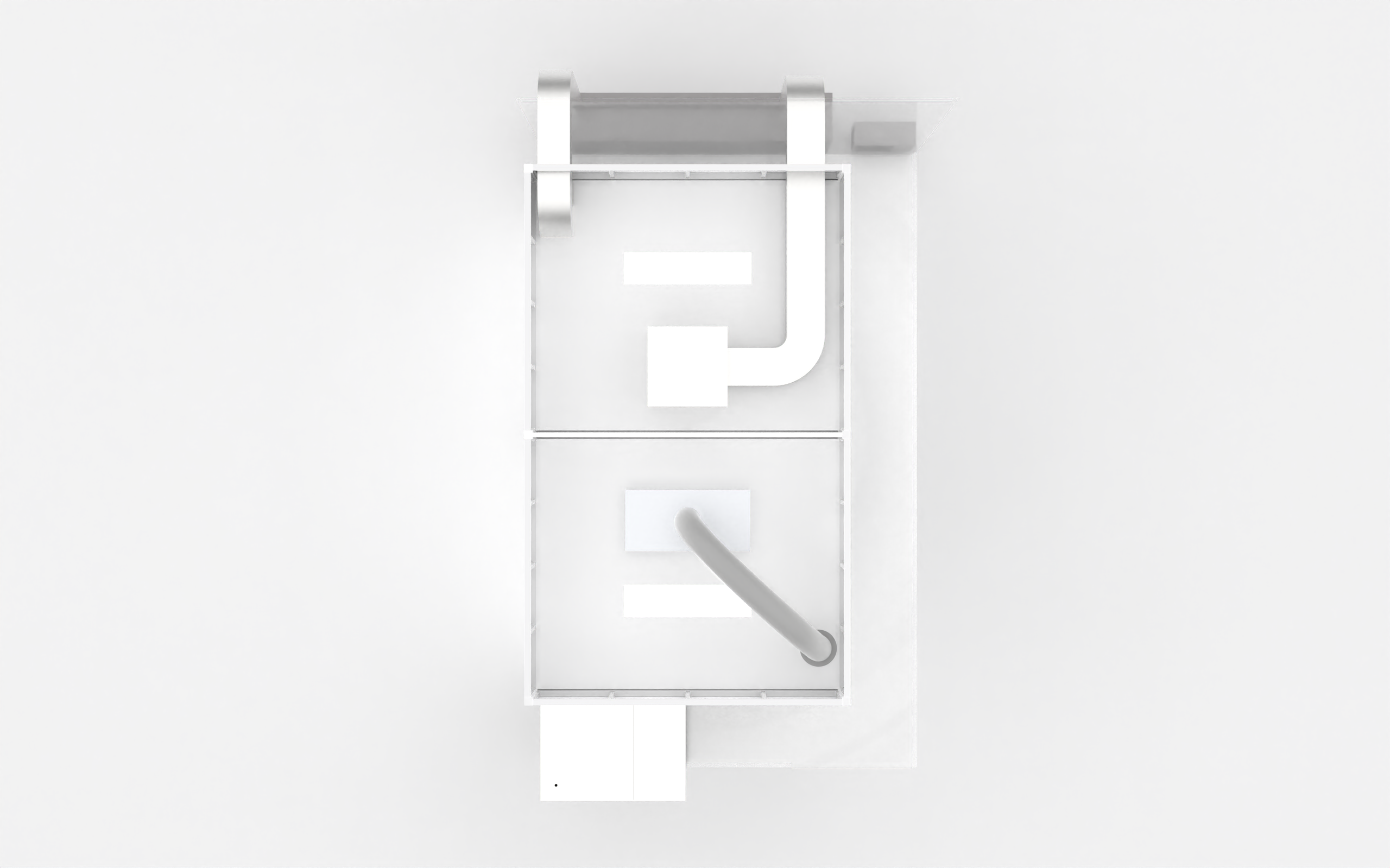

1.Quick installation and easy to set-up

- Modular construction enables quick on-site assembly without heavy civil work

- Ideal for urgent production needs or temporary cleanroom facilities

2.Prefabricated & Flexible Design

- Built from modular wall panels, ceiling grids, and flooring systems

- Easily expandable, reconfigurable, or relocated according to project requirements

- Supports ISO Class 3 to Class 8 cleanliness levels (per ISO 14644-1)

3.Low cost

- Factory-prefabricated modules reduce on-site labor and civil work.

- Minimal disruption to existing operations reduces downtime losses.

- Modular additions avoid rebuilding costs.

Cost Comparison Table

| Cost Category | Traditional Cleanroom | Modular Cleanroom | Notes / Savings Explanation |

| Construction / Materials | High | Medium | Modular panels prefabricated; less civil work |

| Labor / Installation | High | Low | On-site assembly is faster, fewer workers needed |

| Lead Time | 3–6 months | 1–4 weeks | Faster deployment reduces lost production time |

| Relocation / Expansion | Expensive / Difficult | Low | Modules can be reused or added with minimal cost |

| Maintenance / Cleaning | Medium | Low | Smooth, chemical-resistant surfaces |

| Energy Cost | Medium | Low | Targeted airflow and efficient HVAC design |

| Total Ownership Cost (TCO) | High | 30–50% lower | Combined savings in construction, downtime, and operation |

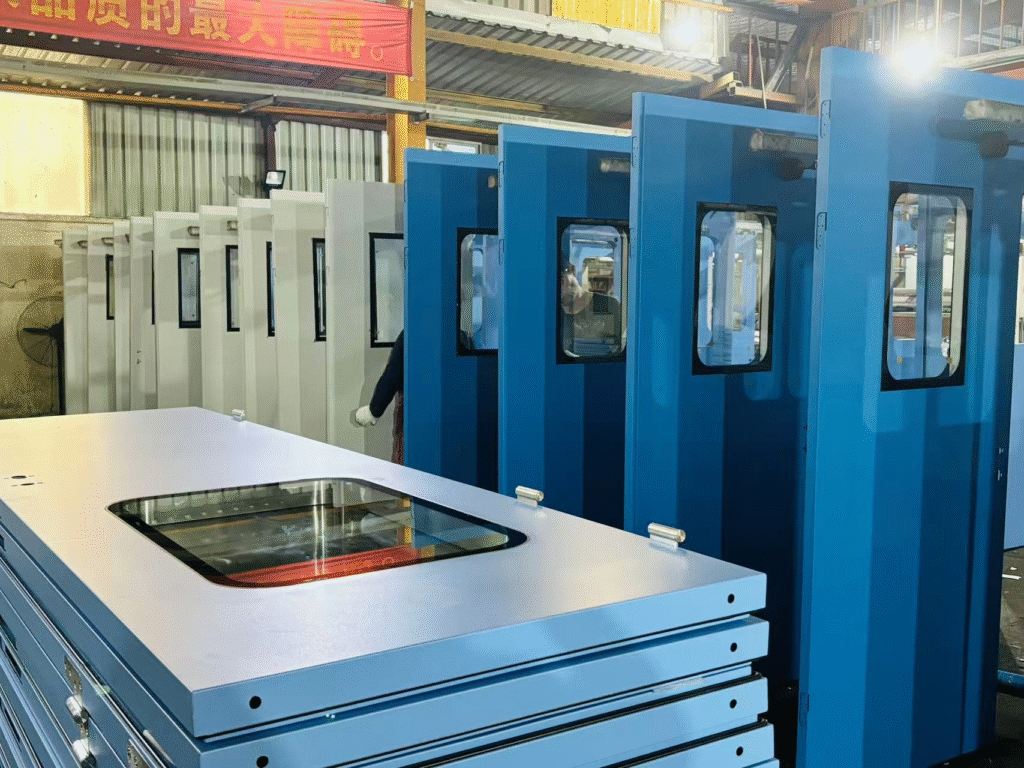

CLEANROOM PANEL SELECTION(MATERIAL)

Cleanroom panels are the backbone of modular cleanrooms. The choice of rockwool, honeycomb, PU/PIR, or HPL/stainless-steel panels depends on project requirements such as fire resistance, cost, chemical exposure, and cleanliness class. Proper selection and installation guarantee both performance and long-term cost efficiency. We ensure you will find the ideal solution for your needs, Contact us and find the best match of your program.

CLEANROOM DOOR SELECTION

Cleanroom doors in modular cleanrooms are not just entry points but critical barriers that ensure airtightness, contamination control, and compliance with ISO/GMP standards. The choice of swing, sliding, or hermetic doors — combined with suitable materials like stainless steel, HPL, or coated steel — depends on application-specific needs such as hygiene, fire safety, and pressure control. JIANGSU YANXIN offers you various kind of cleanroom door, you can find the ideal choice for the best match of your project.

CLEANROOM ACCESSORIES

Cleanroom accessories in modular cleanrooms are not just add-ons; they are essential functional elements that guarantee compliance, improve operational efficiency, and enhance user safety. The careful selection of windows, pass boxes, air showers, covings, lighting, and furniture ensures that modular cleanrooms remain flexible, compliant, and cost-effective throughout their lifecycle.