Cold storage panels, also known as insulated sandwich panels, are widely used in the construction of temperature-controlled environments such as cold rooms, freezers, and refrigerated warehouses. Their core materials—commonly polyurethane (PU), polyisocyanurate (PIR), or rockwool—offer excellent thermal insulation, structural strength, and energy efficiency. These panels help maintain consistent low temperatures, reduce energy consumption, and ensure the safe storage of perishable goods in industries such as food processing, pharmaceuticals, and logistics.

Cold storage panels are designed for quick assembly and reliable insulation performance. With precise joint systems and durable materials, they ensure stable temperature control for cold rooms, freezers, and warehouses.

JIANGSU YANXIN provides the following Installation Steps:

- Preparation – Ensure the foundation is level and clean.

- Wall Panels – Panels are set into floor tracks, interlocked tightly, and sealed to prevent air leakage.

- Ceiling Panels – Roof panels are connected securely to wall panels, with additional reinforcement when needed.

- Doors & Accessories – Cold room doors, lighting, and other fittings are installed to complete the system.

- Sealing & Testing – All joints are sealed, followed by inspection and cooling system testing to guarantee performance.

Products

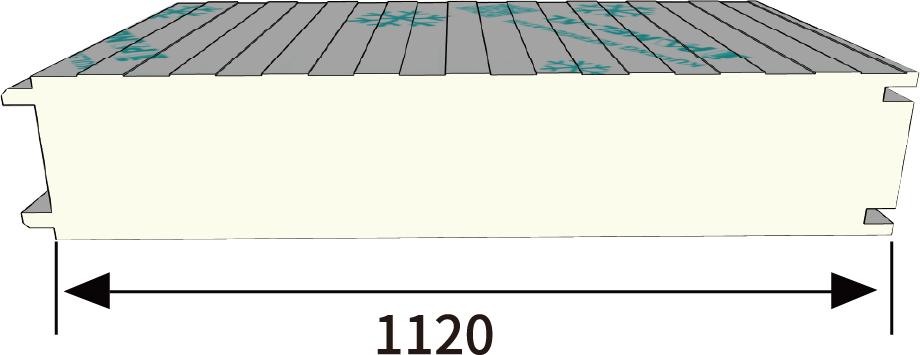

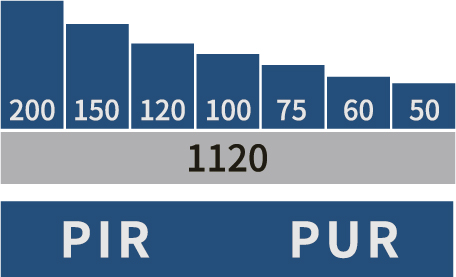

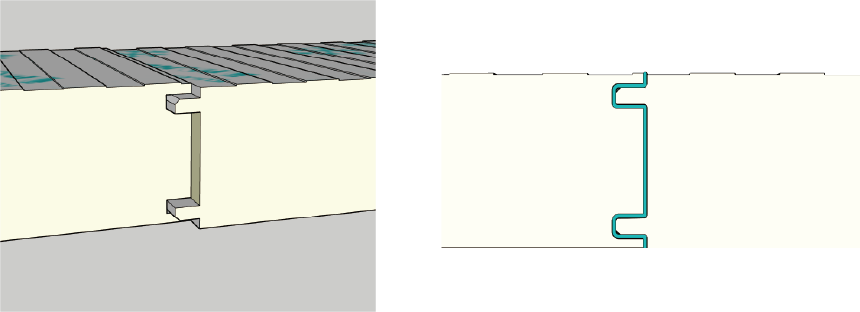

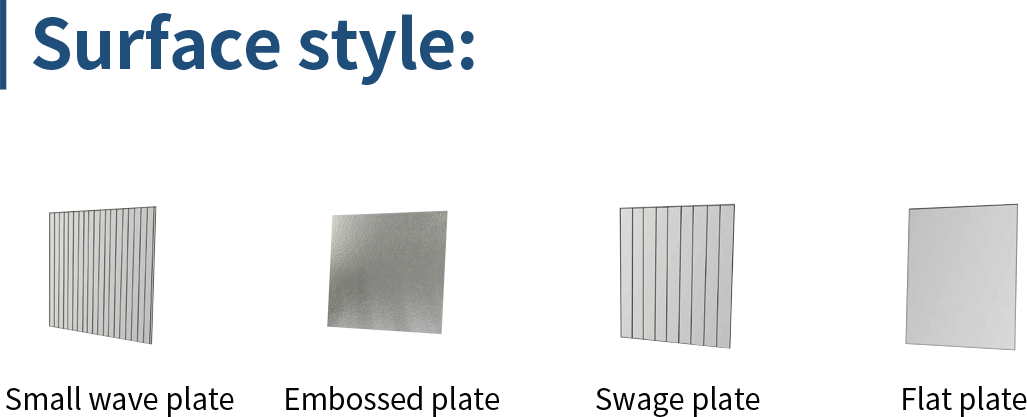

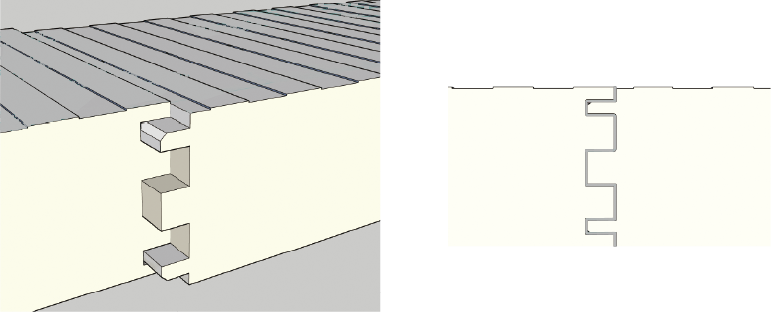

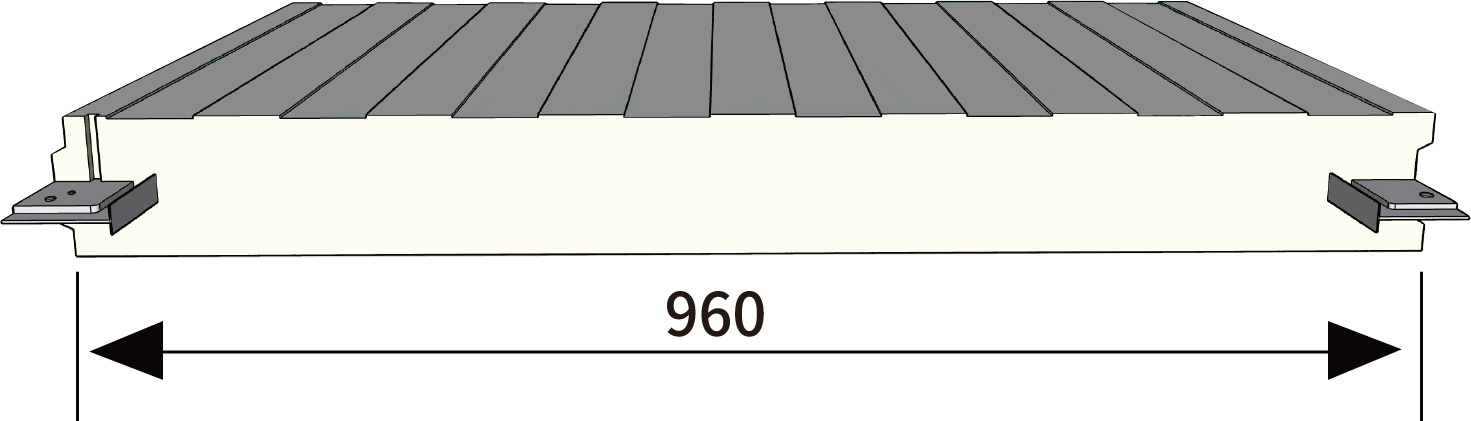

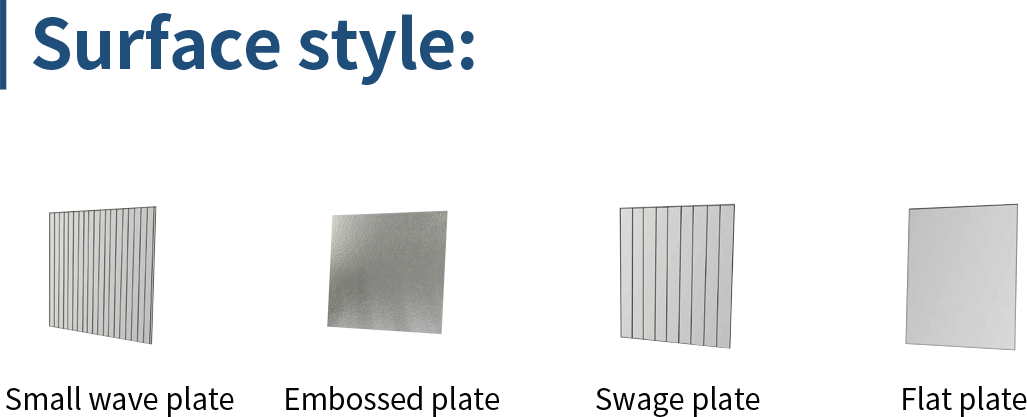

NOTCH NORMA STYLE PIR PANEL

The Norma style shaped notch provides a very good sealing effect for the panel. The panel wrapping notch makes the groove shape less prone to damage, deformation, and detachment, while increasing the bending strength.

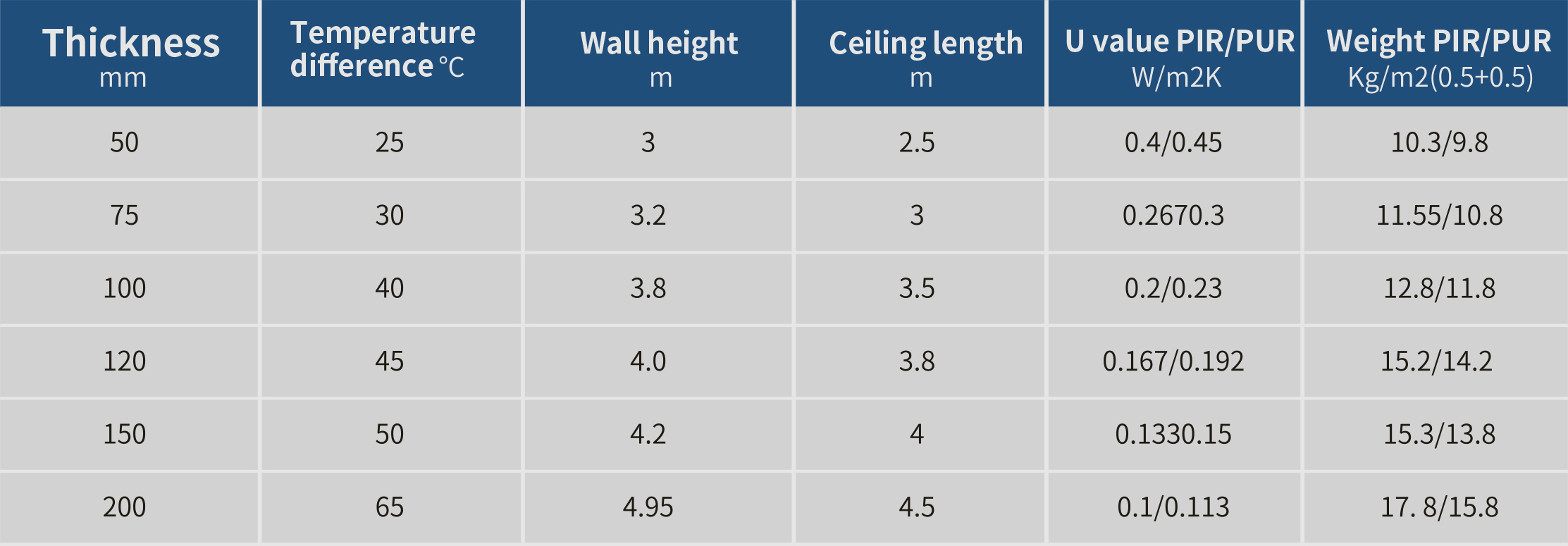

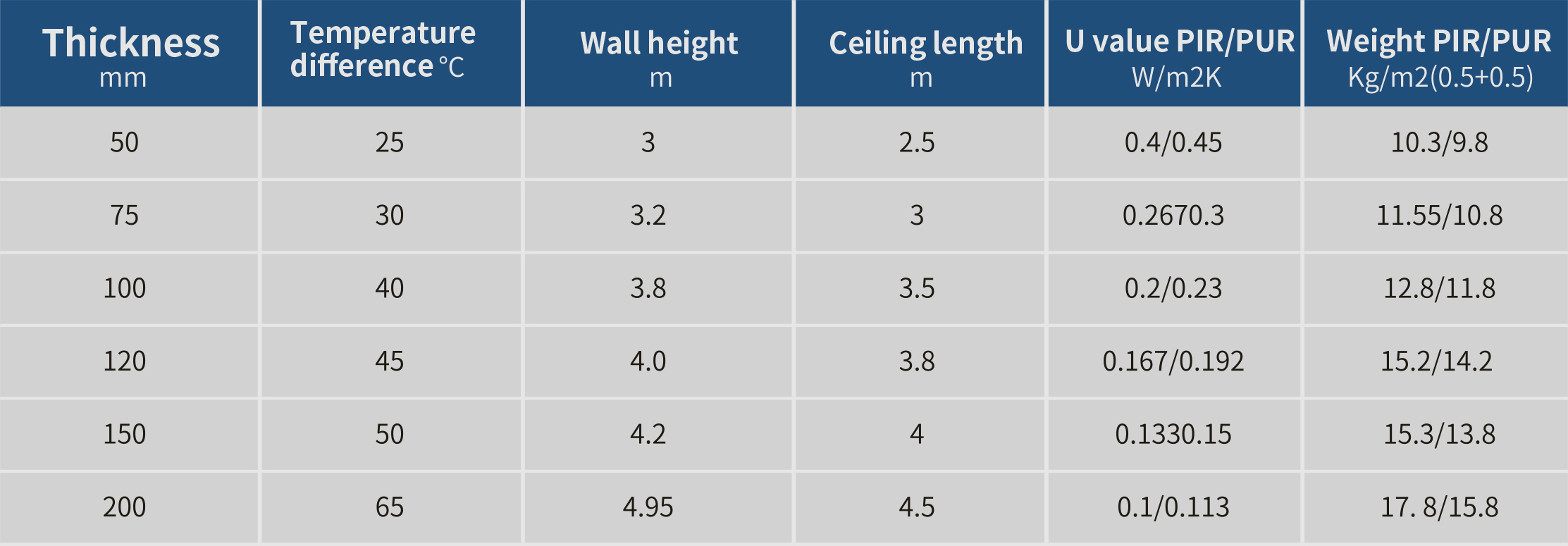

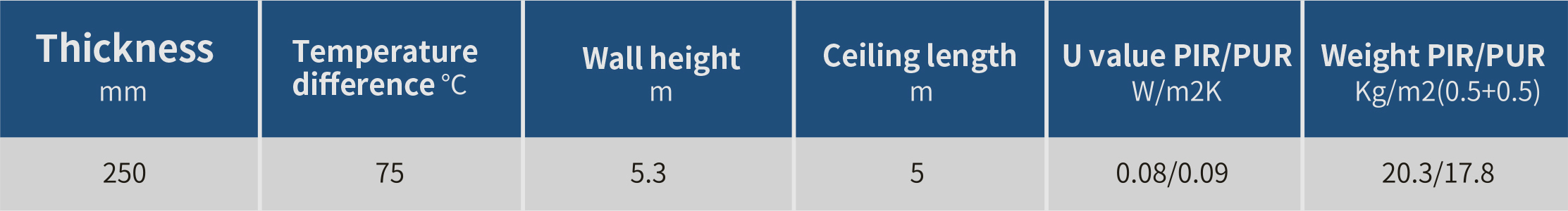

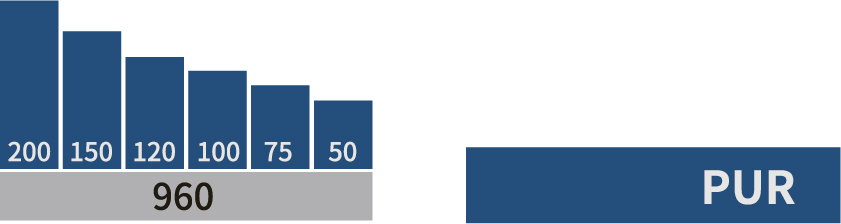

Product performance table

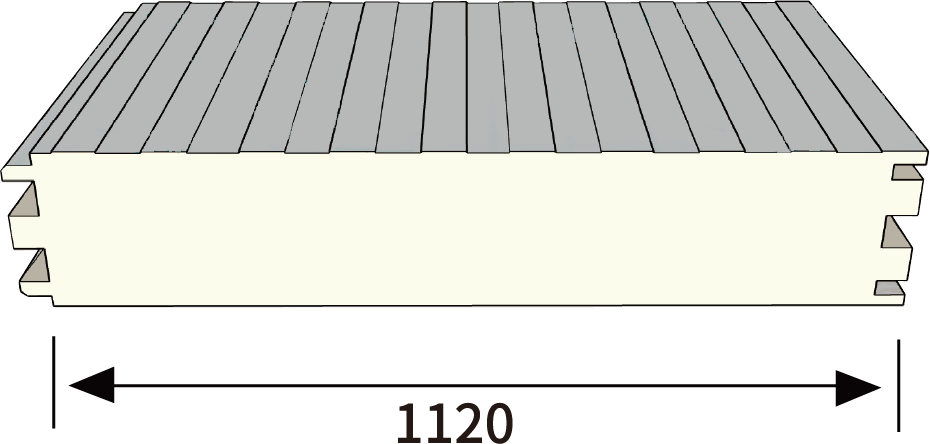

DOUBLE NOTCH NORMA STYLE PIR PANEL

The double notch makes the sealing and insulation more excellent, resisting deformation caused by large temperature differences.

Product performance table

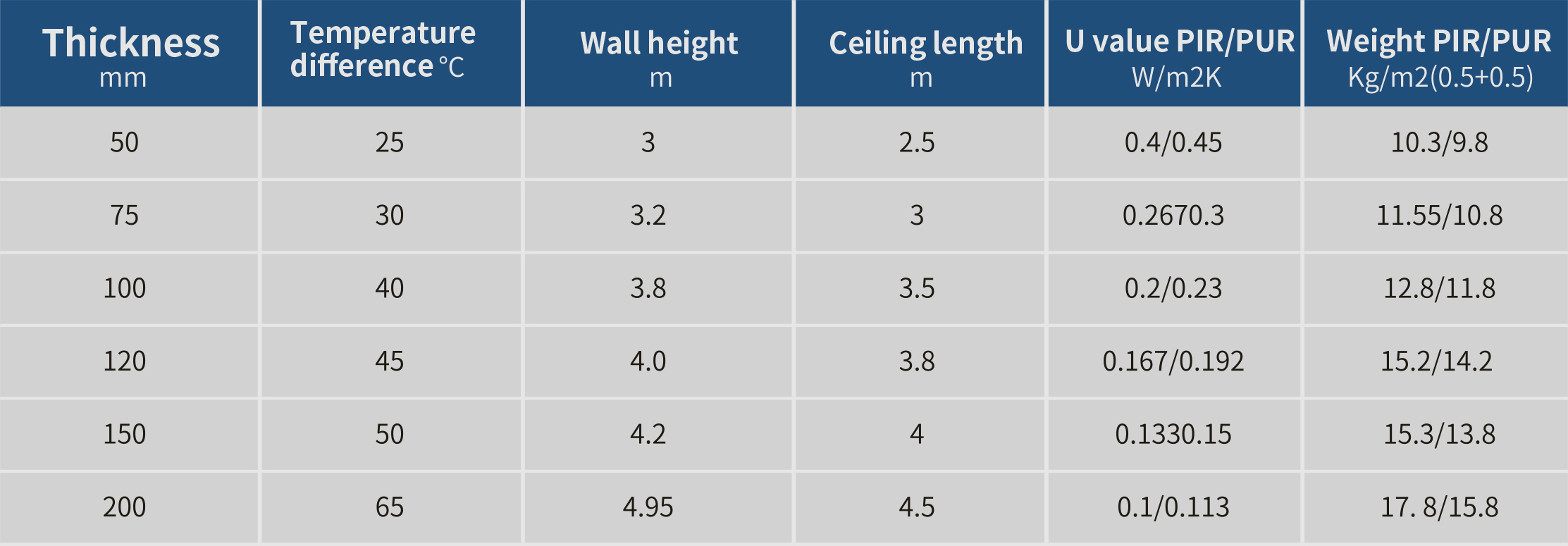

CAM-LOCK PU PANEL

Cam-lock connection makes the installation of cold storage panels convenient, suitable for the construction of small-sized cold storage.

Product performance table

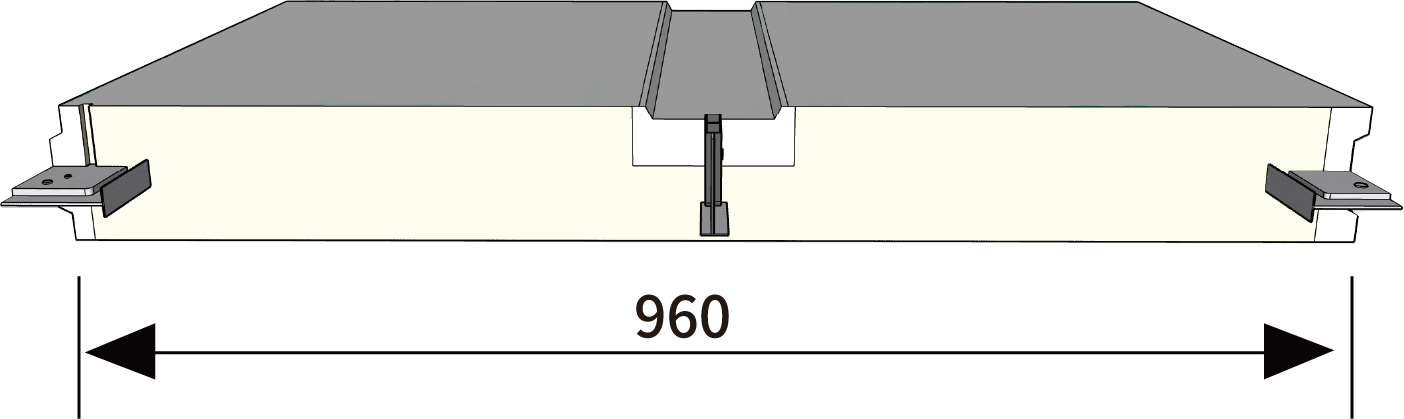

CAM-LOCK BORDER PU PANEL

Using high-density profiles as slot frames and foaming the together with the panel. Can ensure that the slot shape does not deform at various temperatures. Suitable for use in high temperature and humidity environments.

Product performance table