MACHINE-MADE CLEANROOM WALL PANEL

The global demand for mechanized cleanroom panels has been steadily increasing due to the rapid development of high-tech industries, pharmaceuticals, biotechnology, food safety, and renewable energy sectors. With stricter international standards for hygiene, safety, and environmental sustainability, cleanroom construction materials are becoming a critical component in advanced manufacturing and healthcare facilities.

The machine-made cleanroom panels produced by JIANGSU YANXIN feature neater and more aesthetically pleasing profiles, faster processing speed, and more efficient installation, saving both time and labor. They help reduce construction costs and lower the demand for aluminum profile accessories, thereby effectively controlling the overall project cost.

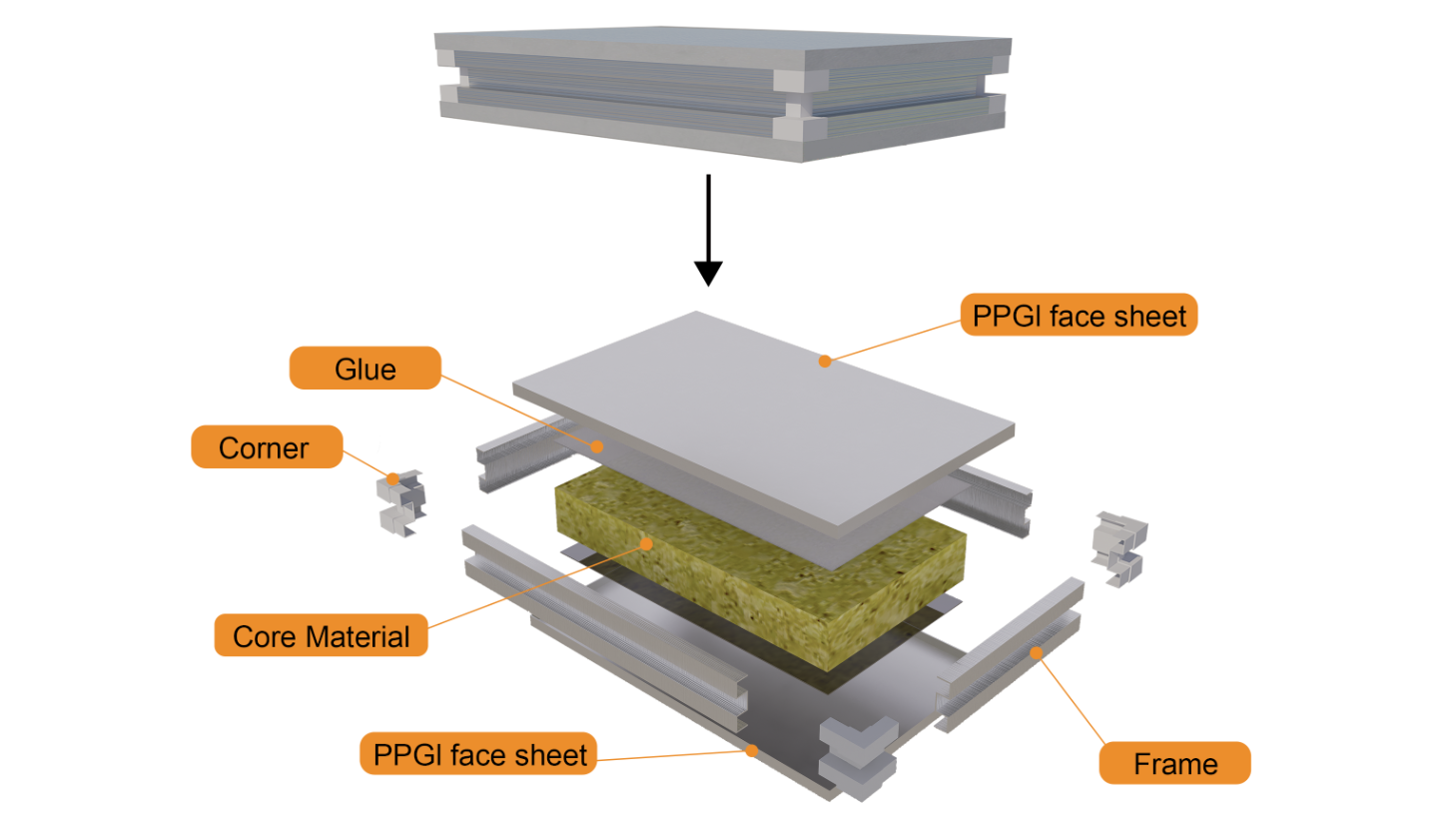

Machine-made Panel Structure

Standard 50mm-thick machine-made rock wool panel

Consists of several main components:

PPGI Panel – The outer surface is made of pre-painted galvanized iron (PPGI) sheets, providing durability, corrosion resistance, and a smooth finish.

Core Material – The middle layer serves as the core insulation material, typically rock wool, EPS, or other fire-resistant and insulating materials.

Frame – Positioned at the sides to enhance structural stability and facilitate installation.

Glue – High-strength adhesive is used to bond the PPGI panels and core material together, ensuring a solid and durable composite structure.

This structure provides thermal insulation, fire resistance, soundproofing, and a smooth surface, making it ideal for cleanroom construction.

Parameter

Product Name: | Machine-made Wall Panel |

Width: | 980mm, 1180mm |

Max Length: | 6000mm, Customized Length |

Wall Thickness: | 50mm, 75mm, 100mm |

Steel Facer Thickness: | 0.4-0.8mm |

Outer Plate Material: | PPGI, Al-mg-Mn Alloy Steel, SS Steel, Ti-Zn Stee |

Coating: | PE, PVDF |

Core Material: | Rock Wool, Magnesium, Paper Honey Comb, Aluminium Honey Comb, PU, silicalite, etc. |

Frame Thickness: | 0.6-0.8mm |

Application: | Pharmaceutical Cleanroom, Electronic Cleanroom, Food Cleanroom, etc. |

Finished Panel

HAND-MADE CLEANROOM WALL PANEL

HAND-MADE cleanroom panels play a vital role in industries that require customized solutions for controlled environments. Unlike fully machine-made panels, HAND-MADE panels allow greater flexibility in size, shape, and structural design, making them suitable for complex projects, non-standard installations, and facilities requiring high levels of customization.

With the growth of personalized medicine, advanced healthcare, high-end electronics, and clean energy industries, the demand for HAND-MADE cleanroom panels is increasing steadily. These panels are often preferred in small-batch, high-value, or highly specialized projects that require precise workmanship and tailored solutions.

The global trend shows a dual demand pattern: while machine-made panels dominate large-scale standardized projects, HAND-MADE panels maintain strong demand in customized, high-tech, and niche applications, especially in emerging markets and high-specification facilities.

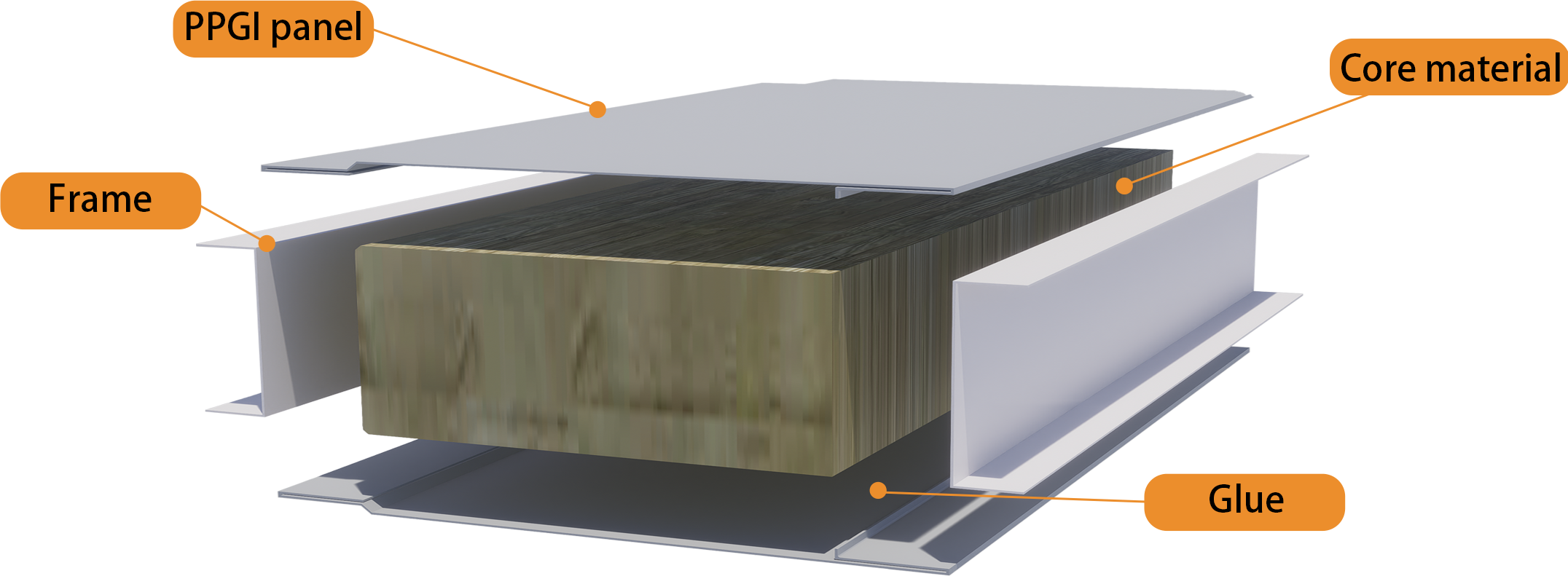

Hand-made Panel Structure

Composed of several key components:

- PPGI Face Sheet– The top and bottom layers are made of pre-painted galvanized iron sheets, providing a smooth, durable, and corrosion-resistant surface.

- Core Material– The central layer serves as the insulating core, often rock wool or other materials that provide thermal insulation, fire resistance, and soundproofing.

- Frame– A surrounding structural frame enhances the panel’s strength and allows for secure assembly and installation.

- Corner Pieces– Located at the panel’s edges, these components ensure a precise fit, sealing, and enhanced stability.

- Glue– High-strength adhesive is used to bond the face sheets, core material, and frame together, ensuring a solid composite structure.

This design allows for greater customization in size and structure, making hand-made cleanroom panels suitable for complex or non-standard projects where flexibility and precise workmanship are required.

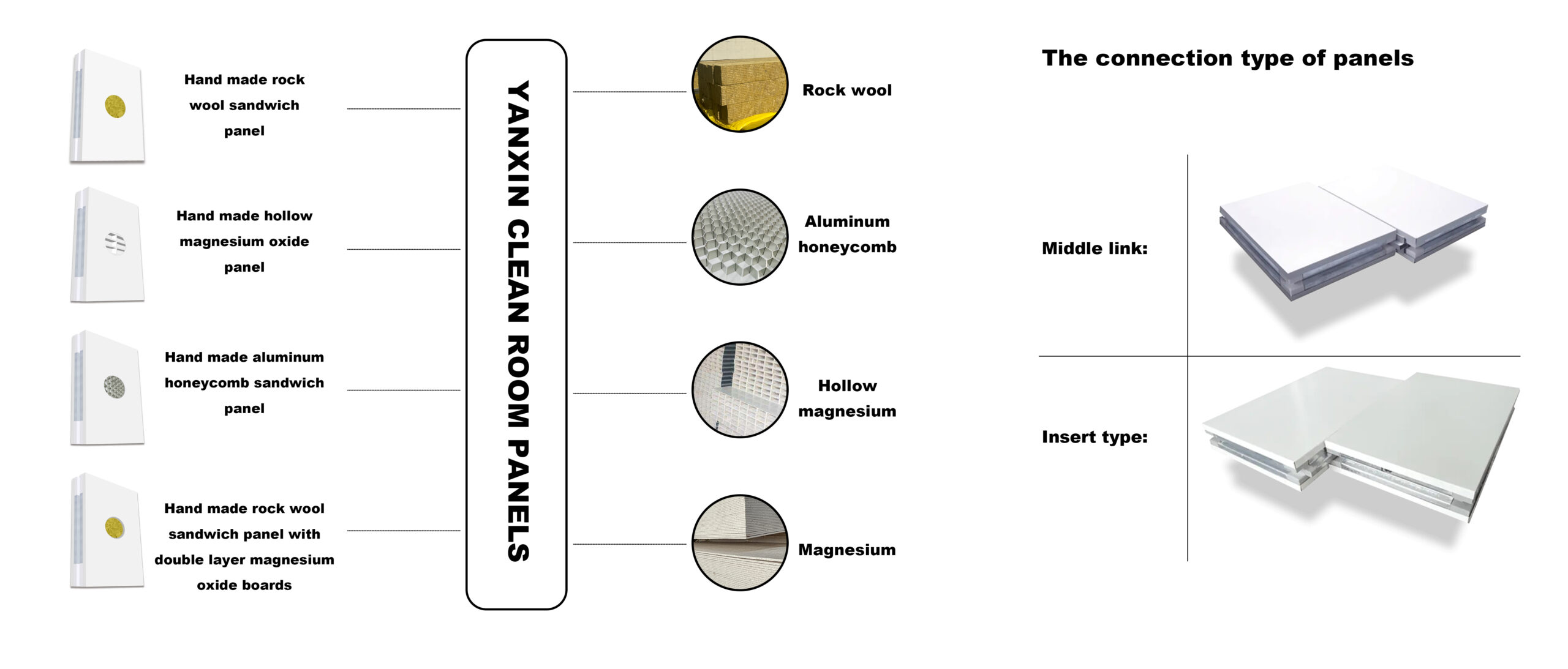

Main Products

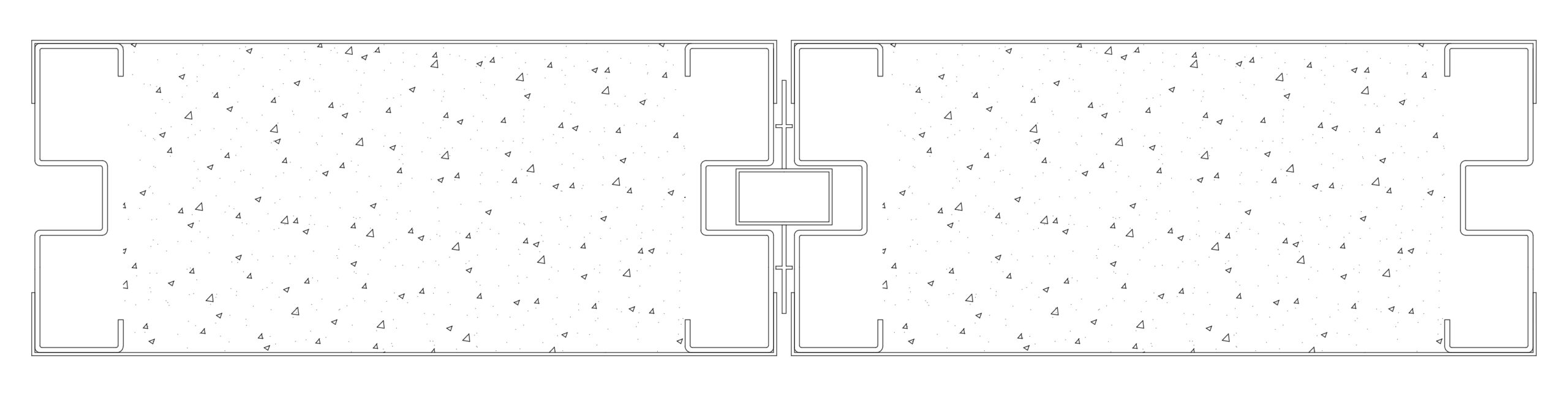

The hand-made panels shown have two main connection types:

Middle Link Connection – Panels are joined using a connector in the middle, creating a secure and tight joint. This method ensures stability and a seamless surface while maintaining good airtightness.

Insert Type Connection – One panel edge is inserted into the other, providing a quick and simple installation. This design reduces the need for additional accessories, saves installation time, and ensures a clean appearance.

Both connection types are designed to achieve efficient assembly, strong structural integrity, and excellent sealing performance, making them suitable for cleanroom construction where hygiene and airtightness are critical.

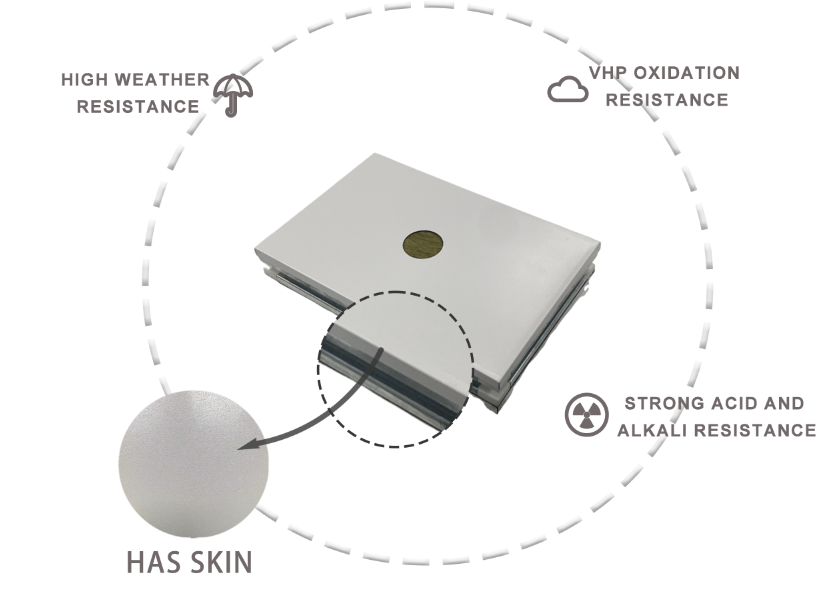

Featured Hand-Made Panel

HAS SANDWICH PANEL is based on high zinc layer galvanized/aluminum zinc plate.

The coating has multiple functions such as high weather resistance, highcorrosion resistance, strong acid and alkali resistance, and VHP oxidation resistance which allows it has following advantages:

Excellent Chemical Resistance

Durable Surface Protection

Smooth and Easy-to-Clean Finish

Good Structural Strength

Parameter

Product Name: | Customized Cleanroom Sandwich Panel |

Width: | 1180mm, 980mm, Customized width |

Max Length: | 6000mm, Customized Length |

Wall Thickness: | 50mm, 75mm, 100mm, etc. |

Steel Facer Thickness: | 0.4-0.8mm |

Outer Plate Material: | PPGI, Al-mg-Mn Alloy Steel, SS Steel, Ti-Zn Stee |

Coating: | PE, PVDF, ASC |

Core Material: | Rock Wool, Magnesium, Paper Honey Comb, Aluminium Honey Comb, PU, silicalite, etc. |

Frame Thickness: | 0.6-0.8mm |

Application: | Pharmaceutical Cleanroom, Electronic Cleanroom, Food Cleanroom, etc. |

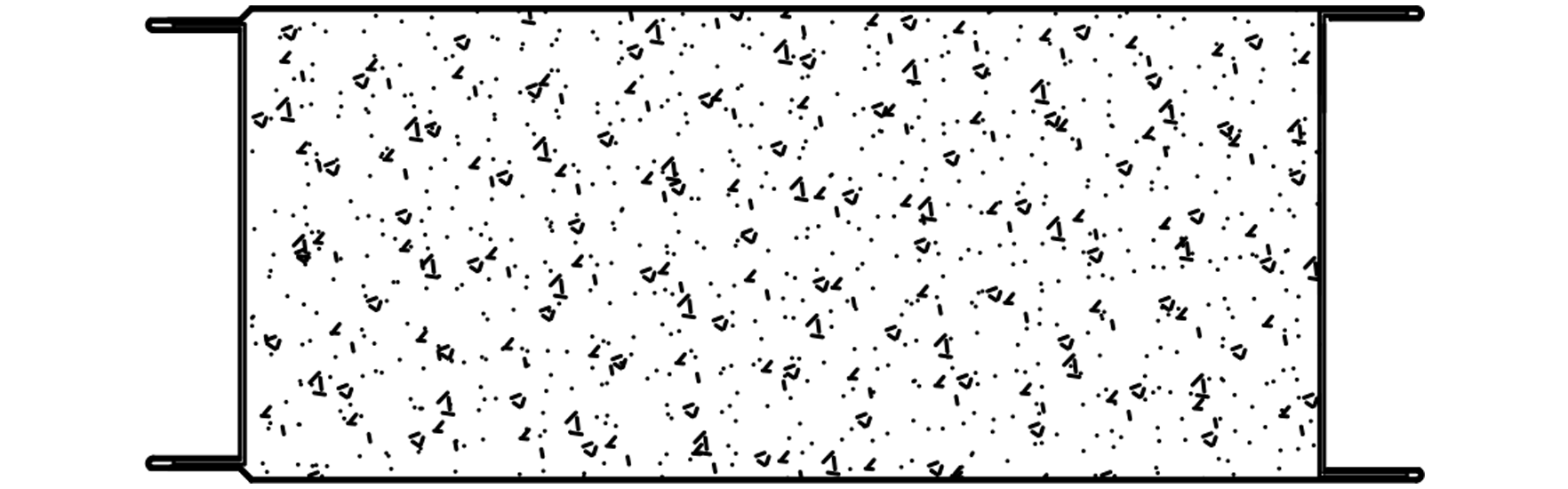

Finished Panel