Cleanroom ceiling panels are a key structural component in modular and conventional cleanroom construction. Designed with lightweight yet durable materials, they provide a smooth, non-particle-shedding surface that meets stringent cleanliness standards. These panels typically feature a metal surface (such as coated steel or aluminum) with an insulated core (rockwool, PU, or other materials), ensuring thermal efficiency, fire resistance, and chemical durability..

A cleanroom ceiling is more than just a structural element – it is an integrated system that combines airflow control, lighting, filtration, and accessibility while ensuring airtightness and easy maintenance. Jiangsu Yanxin provides a complete ceiling solution tailored to diverse cleanroom needs, offering Blind Panels, Machine-Made Cleanroom Panels, and Hand-Made Cleanroom Panels.

Three Types of Cleanroom Ceiling Panels by Jiangsu Yanxin

PRODUCT

Blind Panels

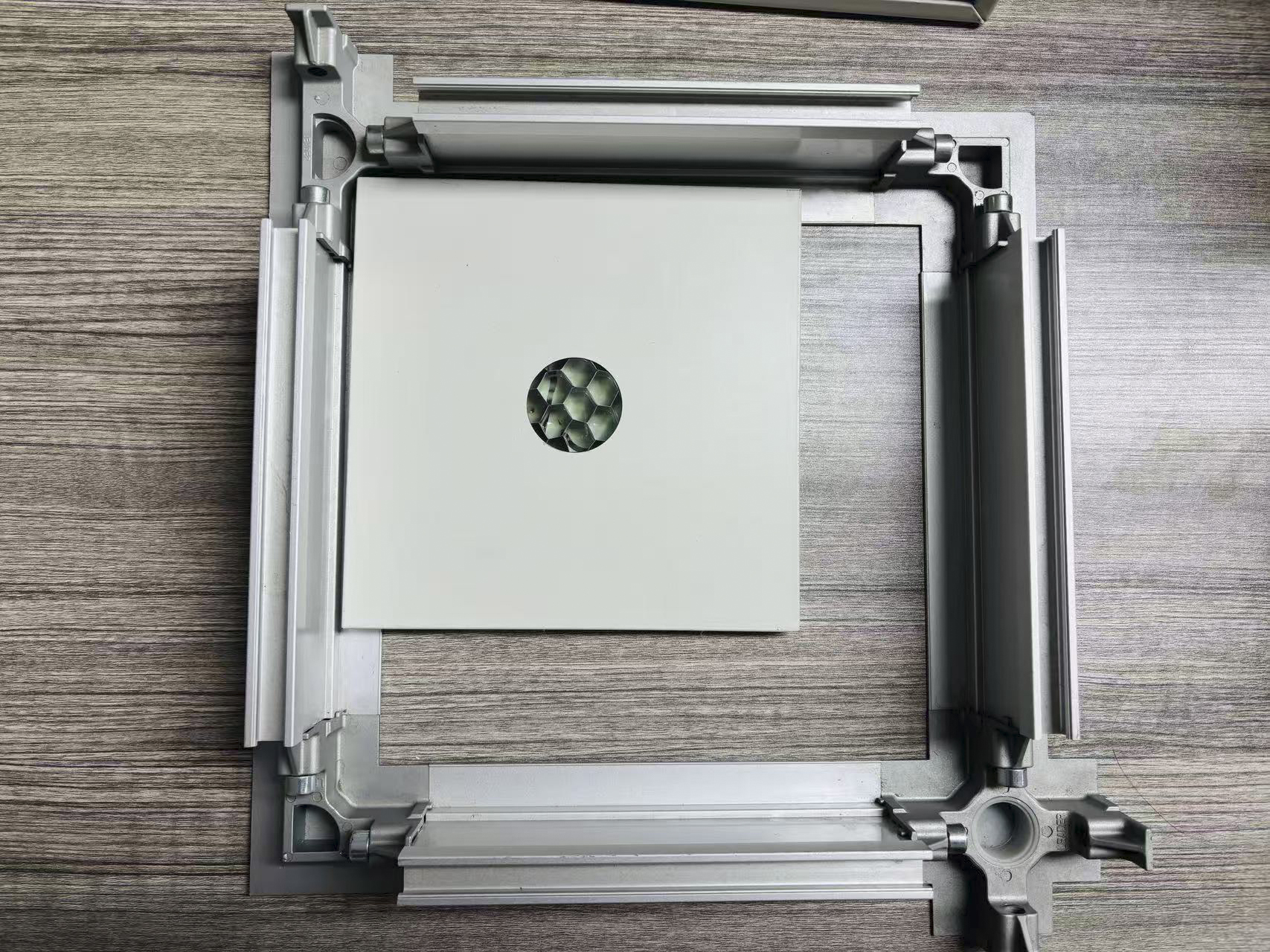

Blind panels are an essential component of cleanroom ceiling systems, mainly used to close off areas where no filters, lights, or equipment are required. At Jiangsu Yanxin, blind panels are typically installed using an FFU keel framework as the supporting structure.

Framework Structure:

The FFU keel provides a stable grid system to support blind panels, ensuring flatness, strength, and alignment with adjacent ceiling modules such as FFUs, filters, and lighting fixtures.

Installation Method:

Blind panels are inserted into the FFU keel framework and sealed with silicone or gaskets to guarantee airtight performance. This design allows quick installation and removal while maintaining the cleanroom’s integrity.

Applications:

Used to fill ceiling spaces around FFUs, lighting, or other equipment, blind panels maintain enclosure continuity and flexibility in ceiling layouts.

Advantages:

Seamless integration with FFU ceiling grids.

Lightweight and easy to handle.

Cost-efficient solution for non-functional ceiling areas.

Maintains the same airtightness and cleanliness as functional panels.

Machine-Made Cleanroom Panels

Machine-made cleanroom panels are widely used for standard ceiling constructions. They are typically supported by a T-shaped aluminum framework (T-bar system), which provides both structural stability and a clean, modular appearance.

Framework:

The T-bar aluminum grid forms a strong and lightweight suspension system. It divides the ceiling into uniform modules, making it easy to integrate panels, lighting fixtures, and filters.

Installation:

Panels are placed into the T-bar framework and connected by tongue-and-groove joints or concealed fasteners. The system ensures flatness, airtightness, and smooth alignment with other ceiling components.

Applications:

Ideal for large-scale cleanrooms in pharmaceuticals, food processing, and electronics manufacturing, where standardized ceiling layouts are required.

Advantages:

Stable and modular suspension system.

Easy installation and replacement.

Cost-effective for large projects.

Compatible with filters, lights, and FFUs.

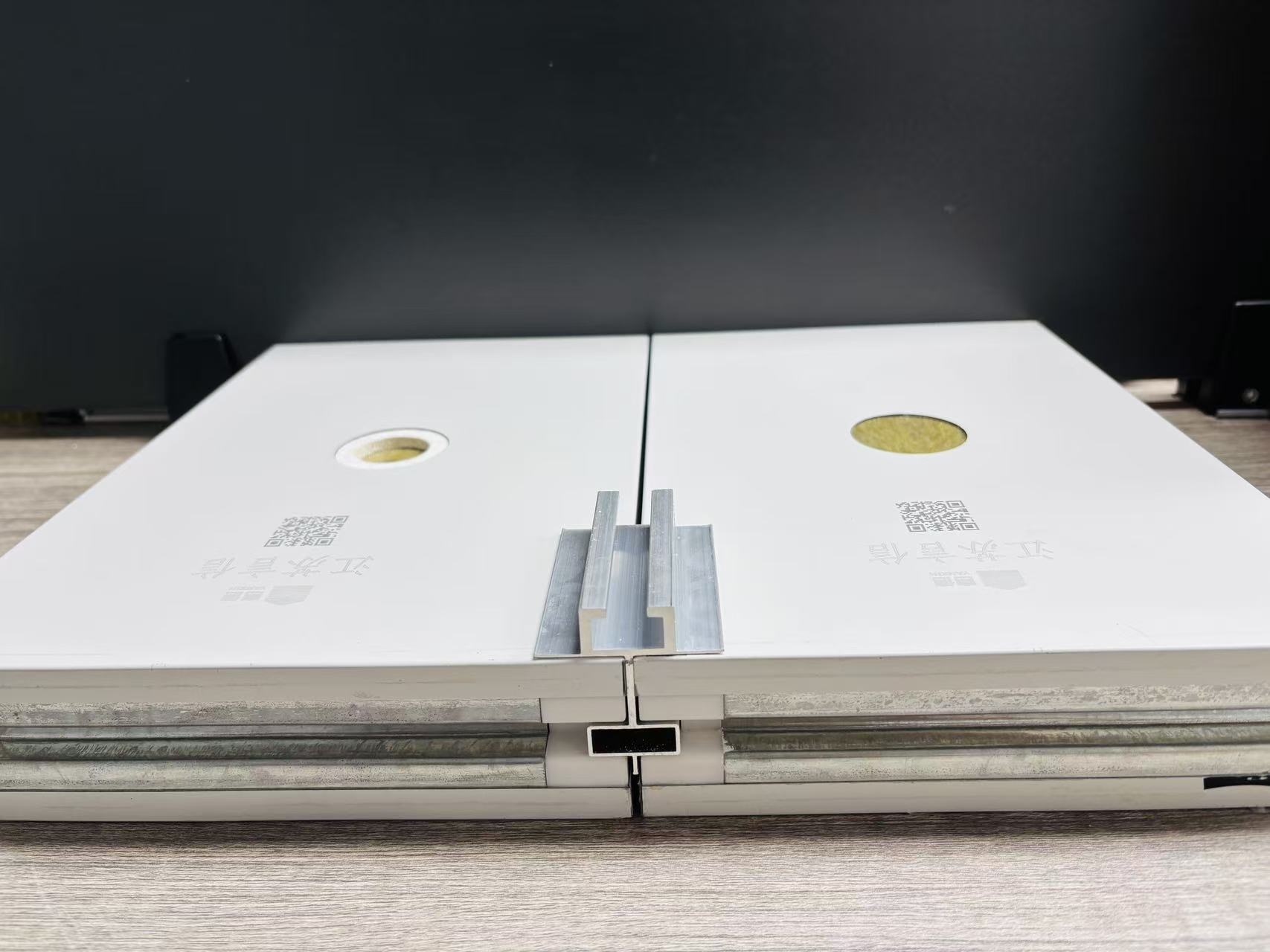

Hand-Made Cleanroom Panels

Hand-made cleanroom panels are highly flexible and can be customized for advanced cleanroom requirements, including walkable ceiling designs. They are commonly installed using a T-Ceiling Hanging Hidden Type framework, which ensures both strength and a seamless, concealed finish.

Framework:

The T-Ceiling Hanging Hidden Type system provides a reinforced suspension structure with concealed connections. This creates a smooth ceiling surface with no exposed fasteners, improving airtightness and aesthetics.

Installation:

Panels are joined by hidden aluminum channels and suspended from the ceiling structure. Reinforced versions allow walkability, enabling safe maintenance above the cleanroom without entering the controlled space.

Applications:

Suitable for high-specification cleanrooms in semiconductors, aerospace, biotechnology, and pharmaceuticals, where strong structural performance and superior sealing are required.

Advantages:

Concealed framework for a smooth, flush ceiling finish.

High airtightness and contamination control.

Strong load-bearing capacity; walkable option available.

Flexible customization in size, thickness, and materials.

Cleanroom Ceiling Systems Overview

Jiangsu Yanxin offers two advanced cleanroom ceiling models: Seamless Panel Ceiling and T-Grid Ceiling. Both systems can be upgraded to walkable configurations, supporting the live load, allowing two operators to safely perform maintenance directly on the ceiling surface.

Seamless Cleanroom Ceiling System

The Seamless Cleanroom Ceiling System is a hermetic, walkable false ceiling solution designed to meet the strictest cleanroom requirements. Its defining feature is the minimization of visible seams, which significantly enhances airtightness and contamination control. This makes it an ideal choice for potent product manufacturing areas, pharmaceutical environments, or cleanroom spaces where airborne particle management and strict environmental stability are critical.

Constructed with modular panels, each unit features a steel frame that supports both live and dead loads, as well as additional hanging loads from utilities, filters, and other accessories. The outer skins of the ceiling panels are manufactured from the same high-quality materials used in cleanroom wall systems, ensuring durability, uniformity, and compatibility across the entire facility. Designed to be walkable, the ceiling can safely support maintenance personnel, with a live load capacity of 35 PSF across the entire surface, allowing operators to perform inspections and service activities directly on the ceiling without risk.

The seamless panels also integrate sound and thermal insulation, creating a controlled interior atmosphere while maintaining cleanroom classification stability. Resistant to humidity and long-term operational wear, they guarantee reliable performance in demanding environments. Installation can be carried out either before or after cleanroom wall placement, offering flexibility during project construction.

Additionally, seamless ceiling panels are engineered for easy integration with plenum cap assemblies, filtration units, and lighting systems. Openings for filters, lights, and utilities are precision CNC-machined at the factory, ensuring accuracy and simplifying on-site installation. Once installed, accessories remain accessible from the top of the ceiling, reducing downtime and simplifying maintenance operations.

T-Grid Cleanroom Ceiling System

The T-Grid Cleanroom Ceiling System offers a versatile and cost-effective solution for controlled environments, commonly used in a wide range of industries including electronics, biotechnology, and pharmaceuticals. This system is based on a T-Grid tile layout, which creates a modular suspended ceiling that can be easily installed, accessed, and reconfigured.

The T-Grid ceiling is compatible with standardized panel sizes and allows for straightforward integration of filters, lights, and utility modules directly into the grid. While it can be designed as a non-walkable or walkable system, the walkable upgrade is engineered to carry up to 35 PSF live load, enabling safe personnel access for maintenance above the cleanroom. For spans of up to 12 feet, the T-Grid ceiling can operate as a self-supporting system when anchored to cleanroom walls. For spans exceeding this limit, the system can be reinforced by the building’s structural ceiling to meet high load-bearing requirements.

One of the primary strengths of the T-Grid system lies in its flexibility and accessibility. Individual tiles or panels can be removed independently, making it easy to service utilities, replace filters, or reconfigure lighting without disturbing the rest of the ceiling. This modularity provides long-term operational efficiency and reduces downtime during facility upgrades or maintenance activities.

The T-Grid system is also highly adaptable in layout design, allowing cleanroom planners to optimize ceiling configurations for different equipment, airflow, and utility requirements. By using lightweight yet durable materials, it ensures structural stability while maintaining compliance with cleanroom standards.

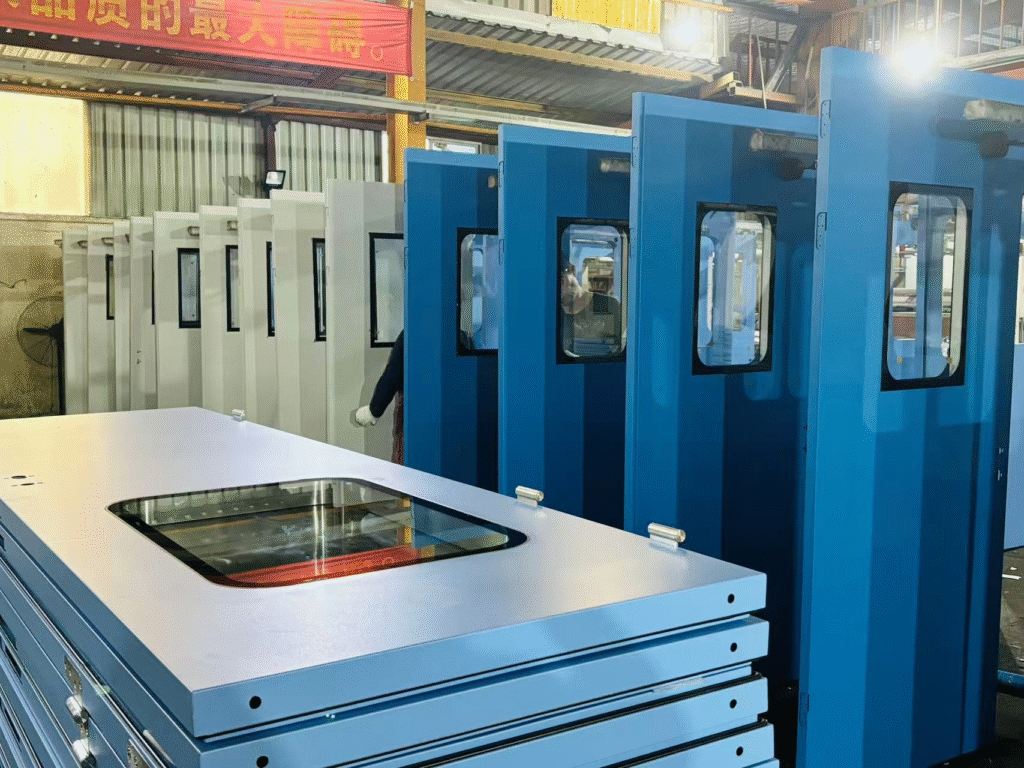

RELIABLE CEILING SYSTEMS, BY TRUSTWORTHY EXPERTS

Leveraging two decades of experience in producing and installing cleanroom materials, our company provides premium-quality panels at the most cost-effective prices, accompanied by excellent service.

CLEANROOM PANEL SELECTION(MATERIAL)

Cleanroom panels are the backbone of modular cleanrooms. The choice of rockwool, honeycomb, PU/PIR, or HPL/stainless-steel panels depends on project requirements such as fire resistance, cost, chemical exposure, and cleanliness class. Proper selection and installation guarantee both performance and long-term cost efficiency. We ensure you will find the ideal solution for your needs, Contact us and find the best match of your program.

CLEANROOM DOOR SELECTION

Cleanroom doors in modular cleanrooms are not just entry points but critical barriers that ensure airtightness, contamination control, and compliance with ISO/GMP standards. The choice of swing, sliding, or hermetic doors — combined with suitable materials like stainless steel, HPL, or coated steel — depends on application-specific needs such as hygiene, fire safety, and pressure control. JIANGSU YANXIN offers you various kind of cleanroom door, you can find the ideal choice for the best match of your project.

CLEANROOM ACCESSORIES

Cleanroom accessories in modular cleanrooms are not just add-ons; they are essential functional elements that guarantee compliance, improve operational efficiency, and enhance user safety. The careful selection of windows, pass boxes, air showers, covings, lighting, and furniture ensures that modular cleanrooms remain flexible, compliant, and cost-effective throughout their lifecycle.